Deep Cycle Redefined: Why Lithium is the Modern Alternative to Lead Acid

For decades, the energy storage industry was dominated by a singular chemical paradigm: the Lead-Acid battery. Because of its historical ubiquity in marine, RV, and solar applications, a persistent misconception emerged—the idea that "deep cycle" is synonymous with lead-acid technology.

In reality, "Deep Cycle" is a performance specification, not a chemical identity. It describes a battery’s ability to sustain repeated, deep discharges over time. Today, the rise of Lithium Iron Phosphate (LiFePO4) has shattered the old paradigm, offering a technological leap that redefines efficiency, longevity, and reliability.

Before diving into the specifics of this evolution, you may want to explore our comprehensive guide on Deep Cycle Battery: Everything You Need to Know to understand the fundamental principles of sustained energy discharge.

1. Technical Analysis: The Paradigm Shift

To understand why the industry is pivoting toward lithium, we must examine the core metrics of energy storage. While the functional goal remains the same, the chemical execution varies significantly. For a more granular breakdown of chemical compositions and safety profiles, see our detailed technical analysis: Lead Acid vs Lithium Ion Battery: What's the Difference?

Below is a professional comparison between traditional Lead-Acid (AGM/GEL) and high-performance LiFePO4 systems, such as those engineered by Power Queen.

Table: Comparative Engineering Metrics

| Performance Metric | Lead-Acid (Deep Cycle) | LiFePO4 (e.g., Power Queen) | Industrial Impact |

|---|---|---|---|

| Usable Discharge Depth | 50% (Recommended) | 80% – 100% (Optimal) | Increased Energy Autonomy |

| Operational Cycle Life | 300 – 500 Cycles | 4,000 – 15,000+ Cycles | Extended System Lifecycle |

| Coulombic Efficiency | 80% – 85% (High loss) | >98% (Minimal loss) | Superior Solar Integration |

| Gravimetric Energy Density | Low (~35 Wh/kg) | High (~100+ Wh/kg) | Significant Mass Reduction |

| Voltage Discharge Curve | Sloped (Linear decline) | Flat (Constant output) | Stable Device Operation |

2. Capacity Utilization: Beyond the 50% Limitation

The most significant engineering constraint of lead-acid is its vulnerability to sulfation if discharged beyond 50%. This effectively doubles the required physical capacity of a battery bank to meet a specific energy goal.

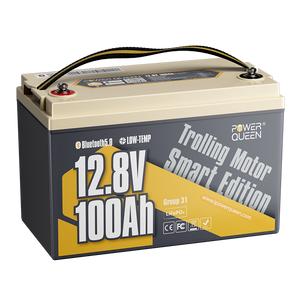

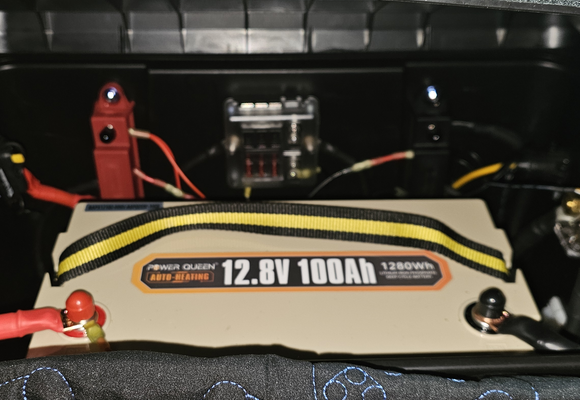

Modern LiFePO4 chemistry eliminates this "hidden" cost. Professional-grade units from Power Queen utilize high-stability Grade-A cells that support a near-full Depth of Discharge (DoD). For the user, this means a 100Ah lithium battery delivers the same usable watt-hours as a 200Ah lead-acid battery, but with a significantly smaller physical footprint.

💡 Read More: AGM vs Lithium Ion Backup Batteries: Why Some Systems Lose Power at 50%.

3. Economic Longevity: Analyzing Cost per Cycle

While the initial capital expenditure (CAPEX) for lithium is higher, a Total Cost of Ownership (TCO) analysis reveals a different economic reality.

- A lead-acid battery typically requires replacement every 2 to 3 years due to chemical degradation.

- A LiFePO4 battery is an asset designed for a 10-year horizon.

When amortizing the cost over 4,000+ cycles, the "price per usable kilowatt-hour" of lithium becomes a fraction of lead-acid’s cost. In professional off-grid applications, lithium is no longer a luxury—it is the mathematically superior investment.

4. Dynamic Performance: Mitigation of Voltage Sag

A critical, yet often overlooked, phenomenon is Voltage Sag. Lead-acid batteries experience a drop in voltage as their state of charge decreases or as high-load appliances are activated. This can cause sensitive electronics to malfunction or shut down prematurely.

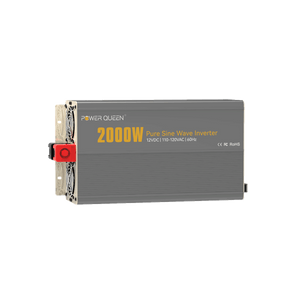

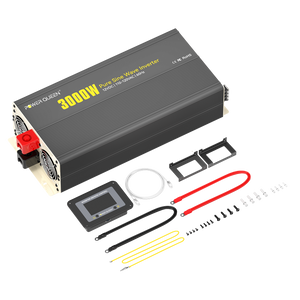

LiFePO4 chemistry provides a remarkably flat discharge curve. Whether at 90% or 20% capacity, the battery maintains a stable voltage. This ensures that inverters, pumps, and appliances operate at peak efficiency throughout the entire discharge cycle.

5. Operational Safety: The Intelligence of BMS

Unlike the passive nature of lead-acid, modern lithium batteries are "active" components. The integration of a Battery Management System (BMS)—a standard feature in the Power Queen lineup—adds a layer of digital protection. This system actively manages cell balancing, thermal regulation, and short-circuit prevention. Furthermore, LiFePO4 is inherently stable and does not emit toxic gases (off-gassing), making it ideal for enclosed living spaces.

6. Frequently Asked Questions (FAQs)

Q: Does Peukert’s Law apply to Lithium batteries?

A: In lead-acid batteries, Peukert's Law dictates that capacity decreases as the discharge rate increases. Lithium batteries are largely immune to this effect, maintaining their full capacity even under high-load demands.

Q: Can I charge Lithium in sub-zero temperatures?

A: While LiFePO4 can discharge in cold weather, charging below 0°C (32°F) is generally restricted to protect the cells. Modern systems often include BMS-managed low-temp cut-offs or integrated heating elements to mitigate this.

Q: Is LiFePO4 environmentally superior?

A: Yes. Lead is a heavy metal with high environmental toxicity. LiFePO4 contains no lead, mercury, or cadmium, and its longer lifespan significantly reduces the volume of waste entering the recycling stream.

7. The New Energy Standard: Embracing the Future

The era where "deep cycle" was a synonym for lead-acid has ended. As we move toward a more mobile and energy-conscious future, the limitations of 19th-century chemistry are no longer acceptable.

By prioritizing Grade-A cell chemistry and intelligent management, Power Queen represents the shift from 19th-century chemistry to 21st-century energy solutions. The future of deep cycle power is efficient, intelligent, and undeniably lithium.