What Is The Torque For A Lithium Battery Terminal?

Understanding the correct torque for lithium battery terminals is crucial for battery performance, safety, and longevity. This article explores why torque settings are important, the risks of incorrect torque, and best practices for maintaining optimal connections for your lithium battery systems.

Table of Content

- Part 1. Why Is Torque Important for Lithium Battery Terminals?

- Part 2. What Happens If the Torque Is Incorrect?

- Part 3. How to Determine the Right Torque for Your Lithium Battery Terminal?

- Part 4. Tools Required for Properly Tightening Lithium Battery Terminals

- Part 5. Best Practices for Lithium Battery Terminal Maintenance

- Part 6. How Environmental Factors Affect Torque Settings

- Part 7. Troubleshooting Torque-Related Issues with Lithium Batteries

- Part 8. Conclusion

Part 1. Why Is Torque Important for Lithium Battery Terminals?

Proper torque for lithium battery terminals is essential for ensuring the safe, efficient, and long-lasting performance of your battery system. When terminals are torqued correctly, they form a secure connection that optimizes the battery's functionality. Here’s why torque matters:

Electrical Conductivity

Applying the right torque to a battery terminal ensures a strong electrical connection. A properly torqued connection minimizes resistance at the contact point, ensuring efficient current flow through the 36V lithium battery. This is especially important in high-demand applications like electric vehicles (EVs) or solar power systems, where energy efficiency is critical.

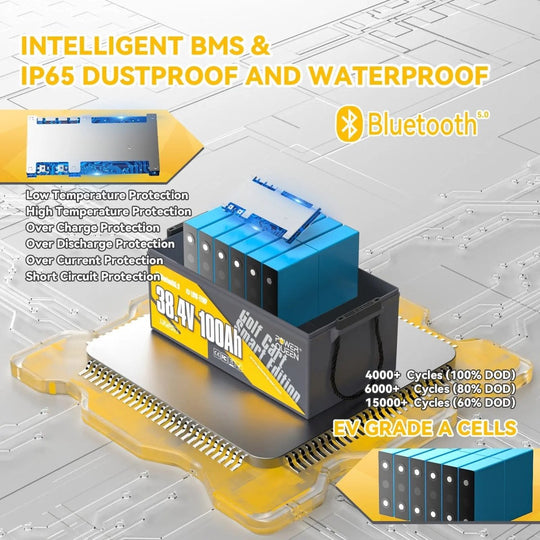

The Power Queen 36V 100Ah Smart Deep Cycle Lithium Battery from Power Queen is designed for high-demand applications like golf carts and electric vehicles, offering Bluetooth 5.0 for easy monitoring. It features multi-tiered BMS protection, low-temp cut-off, and can handle up to 500A peak discharge, ensuring safety and reliability. With a 10-year lifespan and up to 15,000 cycles, it's a durable, lightweight alternative to lead-acid batteries.

Safety Concerns

Torque helps prevent sparks, overheating, and fire risks. Loose terminals create poor contact, which increases resistance and can cause overheating. In extreme cases, it may even lead to thermal runaway. On the other hand, over-tightening the terminals can damage the threads or the battery casing, causing leaks, internal failure, or corrosion. Proper torque avoids these dangerous issues.

Battery Life

Correct torque plays a key role in extending the lifespan of the battery. When terminals are torqued properly, they are less likely to loosen due to vibrations or thermal expansion. This is particularly important in vehicles, machinery, or mobile setups. Consistent torque reduces wear and tear, helping to maintain reliable performance and prolong battery life.

Related Reading: [Full Guide] How Long Do Lithium Batteries Last?

Part 2. What Happens If the Torque Is Incorrect?

Consequences of Under-Torquing Lithium Battery Terminals

Under-tightening can result in loose connections, increased electrical resistance, and overheating, all of which can cause battery failure, thermal runaway, and other safety risks.

Risks of Over-Torquing Lithium Battery Terminals

Over-tightening can damage the terminal, leading to leaks or short-circuiting. Applying just the right amount of torque is crucial to avoid these issues.

Signs of Incorrect Torque to Watch Out For

Look for signs like corrosion, overheating, or unusual battery performance to identify improperly torqued terminals and fix them before they cause damage.

Part 3. How to Determine the Right Torque for Your Lithium Battery Terminal?

To determine the right torque for your lithium battery terminal, the first step is to consult the manufacturer’s specifications for your battery model. These guidelines offer the most accurate torque setting based on the design and size of your battery.

Check the Battery Manual

Always refer to the battery manual for the exact torque values. Manufacturers provide these details to ensure proper installation and avoid damage. Following the instructions carefully helps maintain the warranty and ensures safe operation.

Look for the Terminal Size

The terminal size, indicated by an “M” followed by a number (e.g., M8), can provide an estimate of the required torque. However, this should never be the sole factor in determining the torque; always verify with the manufacturer’s recommendations.

Use a Torque Wrench

For precise tightening, a torque wrench is essential. This tool ensures that you apply the correct amount of torque—neither too tight nor too loose—preventing damage to the terminal or battery and ensuring a secure connection.

Part 4. Tools Required for Properly Tightening Lithium Battery Terminals

Using a Torque Wrench for Accurate Tightening

A torque wrench is the most accurate tool for applying the correct torque to battery terminals. Consider using a digital torque wrench for more precise measurements, especially for critical applications.

Manual vs. Digital Torque Wrenches

There are two main types of torque wrenches: manual and digital. Digital wrenches offer higher precision and are ideal for applications where exact torque is crucial. Manual wrenches, while effective, require more careful monitoring.

How to Use a Torque Wrench Correctly

Follow proper techniques when using a torque wrench. Tighten the terminal gradually to reach the recommended torque value, avoiding over-tightening or under-tightening.

Part 5. Best Practices for Lithium Battery Terminal Maintenance

To maintain your lithium battery terminals in top condition, follow these simple best practices:

Clean Regularly

Use a soft cloth or eraser to gently clean the terminals and remove corrosion or buildup. A cotton swab with a mild cleaning solution can help remove more stubborn dirt.

Apply a Protectant

After cleaning, apply a protectant to the terminals. This creates a seal to prevent corrosion and helps extend the battery's lifespan by keeping the connections clean.

Check for Damage

Regularly inspect the battery cables and connections for any signs of wear, damage, or loose connections. If any issues are found, tighten the connections carefully, avoiding over-tightening which can cause further damage.

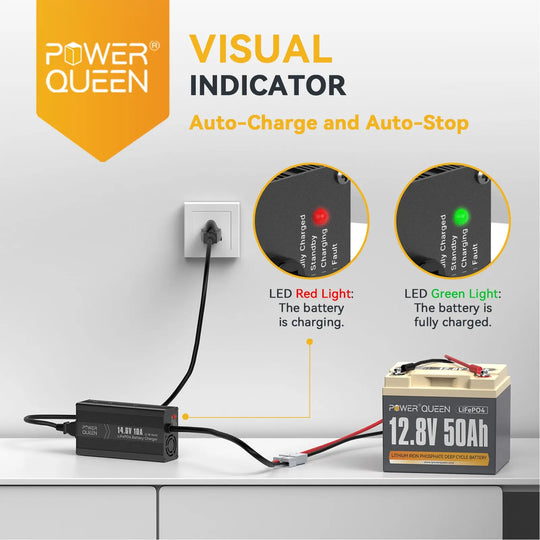

Use a Lithium-Specific Charger

To ensure safe and complete charging of your 36V Lithium Battery, always use a charger designed specifically for lithium batteries, such as the Power Queen Charger. This charger is engineered for LiFePO4 batteries, featuring a fast 2-stage charging process, multiple protection mechanisms, and intuitive LED indicators for easy monitoring.

With premium build quality and high-efficiency charging, it provides the best care for your battery, enhancing both performance and longevity.

Related Reading: [Answered] Can I Charge a Lifepo4 Battery With a Lead Acid Charger

Avoid Fast Charging

Fast charging generates excess heat, which can be harmful to lithium batteries. For everyday use, opt for a slower charger to help preserve battery life and avoid overheating issues.

Related Reading: [Newest] 7 Mistakes to Avoid When Charging LiFePO4 Batteries

Avoid Full Discharge

Avoid discharging your lithium battery completely. Keeping the battery charge between 20% and 80% helps maintain its health and longevity.

Store in a Ventilated Area

Store lithium-ion batteries in a cool, well-ventilated area. Excessive heat or humidity can cause damage, so proper storage conditions are crucial for maintaining the battery’s performance.

Check the Charge Level

If you're storing the battery for a long period, periodically check its charge level. Aim to keep it at around 50% to prevent over-discharging, which can damage the battery’s capacity and lifespan.

Part 6. How Environmental Factors Affect Torque Settings

Environmental conditions, such as temperature, humidity, and air pressure, can significantly influence the accuracy of torque settings. These factors affect the friction between surfaces in a bolted joint, meaning the same applied torque can result in varying clamping forces.

Temperature and Torque Settings

Temperature fluctuations can change the friction coefficient between surfaces. Cold temperatures can reduce friction, while heat may increase it. This causes the required torque to adjust to achieve the desired clamping force.

Humidity and Torque Adjustments

High humidity levels can cause corrosion on metal surfaces, which increases friction. This added friction may require higher torque settings to achieve the proper clamping force, making it important to monitor humidity during torque applications.

Lubrication and Torque Accuracy

Lubricant quality affects friction. Proper lubrication can reduce resistance, helping achieve more accurate torque applications. Always adjust the torque setting based on the lubricant used for optimal results.

Calibration Drift and Environmental Factors

Environmental fluctuations, especially temperature variations, can cause torque wrenches to drift in calibration, leading to inaccurate torque readings. Regular calibration checks are essential when working in changing environmental conditions.

Material Properties and Torque Requirements

Changes in temperature can alter the material properties of bolts and joint components, impacting the required torque. Metals may expand or contract, affecting the way torque interacts with the fastener and material.

Mitigating the Impact of Environmental Factors

To mitigate the effects of environmental factors, perform torque applications in controlled environments with stable temperature and humidity levels. Regularly calibrate torque wrenches and use proper lubrication to ensure consistent torque settings.

Part 7. Troubleshooting Torque-Related Issues with Lithium Batteries

Identifying Loose or Tight Battery Terminals

To check if your lithium battery terminals are improperly torqued, look for these signs:

- Loose Terminals: Look for corrosion or discoloration. Loose connections may cause arcing and heat buildup. You might also notice poor battery performance or voltage drop.

- Tight Terminals: Over-tightened terminals may show cracks or damage. If the terminal or connector is deformed or the bolt threads are stripped, it's likely too tight.

How to Fix Over-Tightened or Under-Tightened Terminals

- For Loose Terminals: Use a torque wrench to tighten the terminal to the manufacturer’s recommended torque setting. Tighten it gradually to avoid causing damage. Clean any corrosion before tightening.

- For Over-Tightened Terminals: Inspect the terminal for cracks or damage. If the terminal is intact, carefully loosen the bolt and retighten it to the correct torque value. Be cautious not to further damage the terminal.

Part 8. Conclusion

Maintaining the correct torque for lithium battery terminals is vital for ensuring safe, efficient, and long-lasting battery performance. By following the manufacturer’s torque recommendations, using the right tools, and practicing regular maintenance, you can optimize your battery’s performance and avoid costly repairs or replacements. Always ensure the proper connection and torque settings to preserve both the safety and longevity of your battery system.